Wireless Modbus

In building and industrial automation there is still widespread use of wired busses like Modbus and BACnet running over wired interfaces like RS485. Meanwhile, there is a growth in newer protocols like MQTT and IP based versions of the above-mentioned busses.

In many cases, wireless is a strong option to wired interfaces. Specifically in retrofitting existing sites, where cable is extremely costly. The return on investment is much better for wireless.

A wireless system must be adapted to the old protocols for retrofit, but also, be future proof to handle the transition to new modern protocols.

Radiocrafts offers several wireless modules which support transferring Modbus and similar protocols over wireless. Both RIIM™ and RC232™ support RS485 interface. RIIM also has other features beneficial for integrating to modern IP based protocols.

There are several approaches to use wireless modbus in an industrial network, and three options are described below. One option is just easy to use cable replacements, while others include supporting IP based communication and cloud connection. The best option for a given application depends on the specific use case and the key design criteria.

Cable Replacement (Modbus RTU)

In this solution the existing Modbus cable between two RTUs is simply replaced by a RIIM Border Router (BR) on one side, and a RIIM Mesh Router (MR) on the other side.

Advantages:

- Easy to use

- Plug and place for retrofitting

- Can include battery operated sensor emulating Modbus devices

- Multiple ways to do commissioning and network management:

- Simple commissioning with buttons to change joining mode

- DIP switches and SW that scan the position at start-up

- NFC/BLE

- SPI/I2C to external controller

- As Modbus writeable/readable data points

- Via SW upgrade

- MODBUS sensors can easily be discovered by the mesh router scanning Modbus addresses

In a network you will be able to set and read different parameters. For example:

- Write a specific network ID (PAN ID) to the node

- Tell the node to leave this network

- Reset a device

- Set Baud rate for MODBUS

- Readout RSSI to parent

- Write encryption keys to a node

- Adjust MODBUS timeout

- Tell the border router to allow new devices to join

- Readout network topology

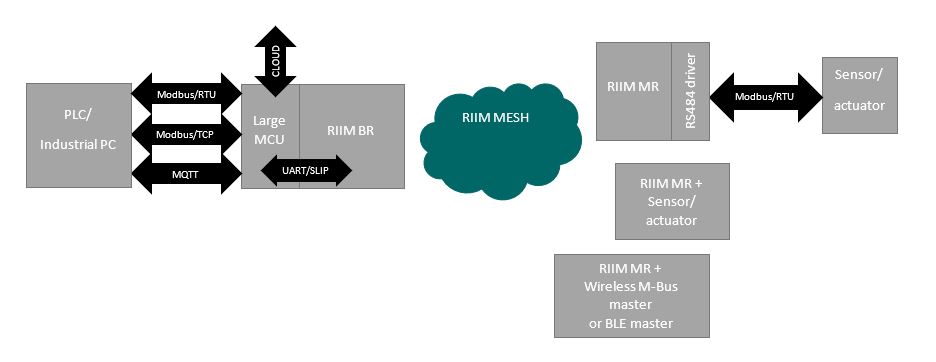

Future-Proof Architecture – Basic

In this solution there is a lot of flexibility in how Modbus is terminated with the PLC, industrial PC or gateway. Popular integrations such as MQTT is supported by easy to use code examples on github.com/radiocrafts/.

Advantages:

- Flexible with regards to external interface Modbus /TCP, Modbus RTU, MQTT etc.

- Cloud connection easily integrated.

- Commissioning/Network management is easy to do through linux host.

- Over-The-Air is easy, also from the cloud.

- Basic edge computing possible.

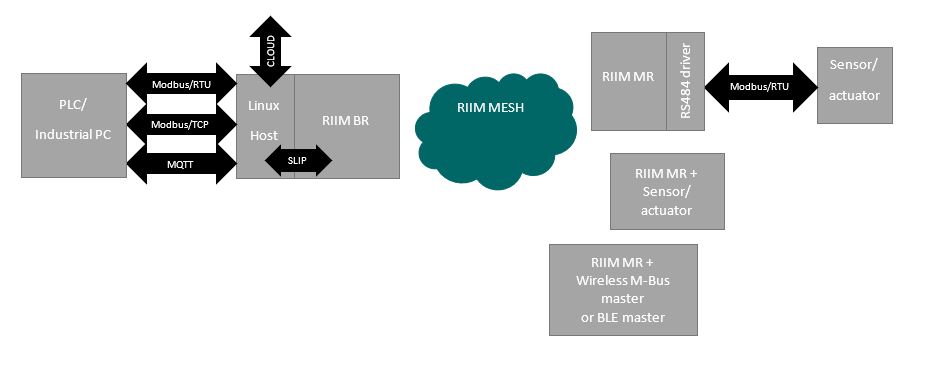

Future-Proof Architecture – Pro

The difference from basic variant is a linux host which makes it easier to support new protocols and add edge computing.

Advantages:

- Flexible with regards to external interface Modbus /TCP, Modbus RTU, MQTT etc

- Cloud connection easily integrated

- Commissioning/Network management can be done through linux host

- Over-The-Air is easy, also from the cloud

- Edge computing possible

Learn more about our RIIM and RC232, our wireless modules which support transferring Modbus and other similar protocols over wireless:

Read our application note, “AN053: Wireless Extension of Industrial Fieldbuses”, where we briefly go through some of the most common serial connections available between nodes in industrial control networks. Afterwards, we present how Radiocrafts RC232 and RIIM solutions enable the wireless extension of some fieldbuses based on Modbus protocol by supporting the RS232 and the RS485 electrical standards on RF modules.

Similarly, buy a RIIM Development kit and test our RIIM Modbus Master code example on GitHub!