Radiocrafts offers turn-key design, customization of modules and direct support to clients that engage in high volume module business with Radiocrafts.

Short Time To Market

Low risk development

Cost effective re-use of Radiocrafts experience base

Our design and direct support services have allowed clients to create very efficient RF solutions with short development times for various design challenges, even when their in-house design resources were not sufficient or occupied in other projects.

The areas of expertise where Radiocrafts has long experience in are:

– Customization of antenna and/or the antenna matching

– PCB layout, particularly for RF

– Power management (low power battery operation)

– Design for EMC compliance

– Complete turn-key designs (production ready)

– Certification for CE and FCC compliance

– Customization of the RF module

- New frequency bands or radio regulations

- Adaption of the protocol stack

- Customized control for autonomous solutions

- Customized interfaces (sensors, pulse inputs)

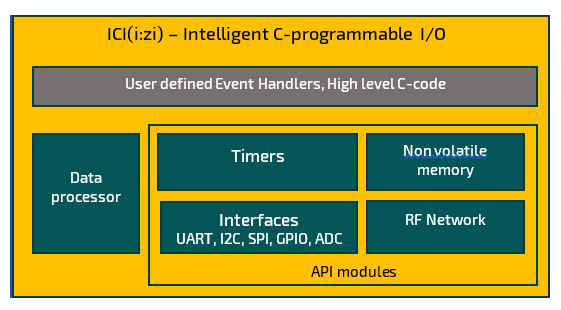

Design and Direct Support Services for RIIoT and RIIM, Using The ICI Framework

A special case for Radiocrafts regarding Turnkey solutions is if the modifications required can be done in Radiocrafts’ ICI framework. ICI is supported by the RIIM and RIIoT Modules. The effort and costs will be at a minimal compared to a traditional turnkey contract design. The ICI application code can be upgraded with Over the Air (OTA) downloads when the network is already deployed and fully operational, which makes the solution “future proof”, as new applications and functionalities can be added when the need arises.

Examples of modifications that can be done in Radiocrafts ICI framework include:

- Adaptation to Sensor/Controller Interfaces

- Scheduling of sensor readings and data transmissions for autonomous operations

- RF tuning for local requirements

- Turnkey design of a complete sensor node

- and much more.

Please contact Radiocrafts to discuss the specific case.

Examples of Radiocrafts design projects

Emergency call system for hospitals and nursery homes

The client needed to make an emergency call system for hospitals and nursery homes. The initial client idea was a solution based on our KNX modules. However, after considering all requirements in the project, we proposed a solution based on our Wireless M-Bus modules. The system consists of several different units; to activate an alarm, to acknowledge an alarm was received, a controller unit and display. The control unit was designed with an external micro-controller using a standard Wireless M-Bus module as a radio modem. The other units, like the battery-operated alarm button, was implemented with customized firmware based on the Wireless M-Bus module, without any external micro-controller.

We did PCBA (Printed Circuit Board Assembly) design for several units. The HW and FW were characterized and approved, and the units were tested for CE compliance. All documentation was handed over to the EMS doing the manufacturing of the units. All the plastic parts were provided by the client. For the production test, we supported the EMS to design an efficient test system. As the RF modules were already tested in the Radiocrafts automatic test system (ATS), only functional testing of the final PCBA was required, saving time and equipment in the final test.

The project was completed on time and the product went into production as planned.

Wireless smoke detector

The client in this case is a provider of high-end smoke detectors. Their existing supplier of the wireless communication modules for the smoke detector should be replaced, and the product was to be redesigned and upgraded. Radiocrafts was chosen due to the competence and level or quality we had already proven in previous projects for the same client.

The new communication module had to be backward compatible with the legacy system. As this was not well documented, the old system had to be reversed engineered. One of the challenging requirements was the battery lifetime. Radiocrafts identified a possible solution using an existing radio module as a starting point for a new design. This saved a lot of time and cost in development, and reduced the risk of the project. The main part of the project was therefore the FW development of the radio protocol that should connect multiple smoke sensors, so that if one sensor is triggered, all should give an alarm.

The customized radio module was designed in a matter of few weeks, based on the standard form factor of other modules. This eliminated the effort to develop special tooling or test equipment.

A PCB (Printed Circuit Board) was designed to hold the radio module, the battery and a compact but efficient antenna. The target for battery lifetime and radio range was achieved. The plastic casing was provided by the client, in order to fit into the existing smoke detector housing.

As the smoke detector should also talk to another building automation system, a second radio protocol was integrated into the same module to convey any alarms. This was possible due the flexibility of the radio module platform.

Full volume manufacturing has ramped up, protecting life, health and property of home owners in Europe.

Water meter clip-on, 6 different projects

Radiocrafts has taken on several projects doing “clip-on” designs which adds radio communication to a mechanical water meter, by detecting the rotation of the index pointer.

- Clip-on 1: PCBA design with pulse interface, battery, supercap, antenna, and IrDa interface, operating at 169 MHz. Radiocrafts developed a protocol with some extra features based on the MBUS4 protocol and the MPC1 pulse counting controller to an autonomous module running the complete water meter application, including pulse counting, IrDa interface for local configuration, and an RF transmission scheduler for meter readings and alarms.

- Clip-on 2: Same project content as Clip-on 1, but adopted to another customer’s requirements.

- Clip-on 3: Same project content as Clip-on 1 and 2, and also added firmware download over-the-air, (OTA)

- Clip-on 4: Similar project as Clip-on 3, but ultrasonic water meter rather than a pulse interface of mechanical meter

- Clip-on 5: Similar as above, without OTA, but not complete HW design, just first PCBA prototypes

- Clip-on 6: Adapted an earlier Clip-on design for new market (geography)

Key features of the designs are that the protocol is customer specific, but also upgradable to standard the Wireless M-Bus protocol. The system was designed for more than 15 years battery lifetime, taking into account the large peak current draw during RF transmission of more than 500 mW for over 100 ms. The high current as well as the radiation from the closely placed antenna required careful EMC design with respect to the low power and sensitive analogue parts of the circuitry; the pulse pick-up system and an optical signal receiver for the IrDa interface.

A major challenge in the project was the constrained size for the antenna. Radiocrafts evaluated several antenna design options, and developed a very compact antenna design that met the radiation requirements of the end client.

Firmware adaption for water meter

In this project we adapted the Radiocrafts MBUS3 protocol to match customer needs and added functionality to reduce active time of the metrology (power saving) for backward compatibility. We also made a 433 MHz variant for non-European markets such as the Middle-Eastern and South-American markets. Time to market was a key concern for the client where the Radiocrafts solution proved successful in terms of shortest design time and ability to adapt to new market requirements.

Customization of the Sigfox module for production testing

Radiocrafts developed a FW variant of the SIG module firmware (Sigfox protocol) where we added another radio protocol to be used in production test, as Sigfox did not provide any local gateway or SLIC at that time.

The new customized module was using the same certified Sigfox stack as the original, therefore saving a lot of time to provide a solution that could help the client get to the market in a short time.

Prototype PCBA for a stand-alone 169 MHz transmitter

The client wanted to do a proof of concept for a pulse counter (from mechanical meter) plus a general sensor input transmitter. The design was for 169 MHz and required a compact but well performing antenna. Radiocrafts designed the PCBA (Printed Circuit Board Assembly) board and provided the first prototypes manufactured by the Radiocrafts EMS partner in a few weeks. This was made possible in a very short time by modifying the modular architecture in the Radiocrafts firmware.

USB stick

A client wanted to add short range radio functionality to their existing gateway design. The gateway already had a USB port, and this was considered to be a good option to add the radio link with no modifications to the existing hardware. The main challenge for the existing Development Board in the new compact form factor was the antenna design. Since the range requirement was not very stringent in this application, a chip antenna was chosen. The antenna was matched to the operating frequency all within the space of a typical USB stick plastic casing. Later the design had been modified to support almost any radio module between 169 MHz and 2.45 GHz.

Gateway expansion board

The IESM board, a gateway expansion board, was originally designed as a custom request. It includes a PCBA design and standard Radiocrafts module.

Even before the term Internet of Things was invented, this was what Radiocrafts was doing. One of the earlier projects in this field was monitoring rat traps installed by a service company for customers storing and handling food products. By getting an alarm from the rat trap, the service provider did not have to send people every day to check if there was a “catch”. The traps were equipped with a detector and a radio transmitter designed by Radiocrafts. The receiver should receive the alarm and send an SMS to the service guy looking after the traps. For this purpose, a gateway was needed that could forward alarms to the “cloud” and also send an immediate SMS. A rugged GSM modem from Sierra Wireless was identified as a good platform as it had the option for an expansion board where the radio module could be added. Radiocrafts designed this expansion board (IESM board) for the Sierra wireless GSM modem. A partner company developed the software for the gateway providing a complete solution to the customer.

The system was completed and field tested within a few weeks, saving the service operator a lot of travelling and useless customer visits, reducing operation cost.